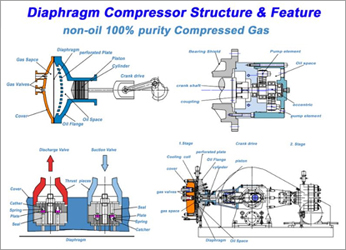

A diaphragm compressor on the other hand works on a different design principle. See principle of operation below. First there are no dynamic seals containing the process gas. Therefore, the leakage from the compressor can be controlled to a very low level by the selection of the "static" seals. For the vast majority of applications elastomeric "O" rings are acceptable and will provide extreme leak tightness depending on the process gas, size of the unit and the pressure.

While it is true that there is permeation of the gas through the "O" rings, for most users they consider a diaphragm compressor leakage free. In extremely critical applications metal to metal seals are available that will initially pass and maintain leak rates of 1 x 10-8 scc/sec or better with helium gas at full operating pressures. For most applications "bubble tight" is more than sufficient.

Second, there are no lubricants or coolants in the process gas stream so there is no contamination of the process gas with any liquid. For practical purposes the gas leaving the compressor is as pure as the gas entering the compressor. Keeepwin Manufactured Diaphragm type compressors are used for handling the purest bottled gases, breathing gas and critical industrial applications.

Generally diaphragm compressors are used primarily where leakage and/or contamination are undesirable or completely unacceptable. Because of the high pressure capability of diaphragm compressors, they are also used at pressures beyond the capability of most oil free or non-lubricated compressors. Typical applications are as follows:

|