- Home Page

- Company Profile

-

Our Products

- API 618 Reciprocating Compressor

- Diaphragm Compressor

- Integrated Compressor

- Scroll Compressors

- Screw Compressor

- Reciprocating Piston Compressor

- Reciprocating Compressor

- Natural Gas Compressor

- Hydrogen Gas Compressor

- Oxygen Gas Compressor

- CO2 & LPG Gas Compressor

- Fast Delivery Oxygen Booster Compressor (Piston)

- Membrane Nitrogen Booster Compressor

- Piston Compressor Air Valve Spare Part

- Water Chiller

- Medical Oxygen Gas Equipment Machine

- Compressor Equipment

- Compressor Spare Part

- New Items

- Extra Link

- Contact Us

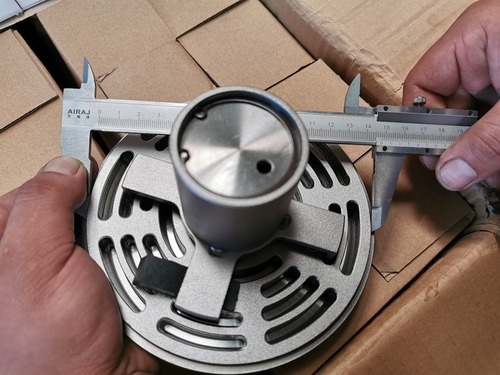

Austria LMF Air Valve Special customize

368 USD ($)

Product Details:

X

Austria LMF Air Valve Special customize Price And Quantity

- 368 USD ($)

- 5 Piece

- 100.00 - 600.00 USD ($)

Austria LMF Air Valve Special customize Trade Information

- Shanghai

- Paypal Western Union Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque

- 3000 Piece Per Month

- 30 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- carton and wood

- Australia North America Eastern Europe Middle East Africa South America Western Europe Asia Central America

- All India

Product Description

Our company specializes in the production of compressor air valves, piston, valve seats, air valve components, intake valves, exhaust valves, etc. Products are made of 3Cr13, 2Cr13, 45#, cast iron, aluminum valve, peek, wire cutting, 3Cr13 stainless steel valve, 17-7PH spring.

Domestic manufacturers of matching imported compressor gas valve accessories of Cook compressor, Austria LMF compressor, ABC Spain, dresser Rand, AF, Belize, Hanwell and other imported compressor.

Descriptionfor SF-10/200 Piston Air Compressor

SF-10/200Piston air compressor is mainly used for pipeline pressure test, sweeping line,gas lift and other projects in oil exploitation, and can also be used as a gassource with air volume of 10m3/min and pressure ≤20MPa for other projects inthe national economy. The compressor allows the user to step down pressure touse.

Thecompressor unit is in skid-mounted form, consisting of compressor maincompressor, diesel engine, gas pipeline system, cooling system and controlsystem. It is composed of a unit and is mounted on the whole skid-mounted andinner a metal cabinet.

Thecabinet body is made of a metal cover, the top of the cover is opened with avent, the exhaust port of the diesel engine is located outside the cover, andthe exhaust muffler of the diesel engine is mounted on the top of the cover.The inside of the cabinet is provided with a lighting lamp, the door isprovided with a lock, the front part is set as an operation surface, and theinstrument operation cabinet leading to the unit is installed in the operationbox. The lower part of the whole set is equipped with a lifting device, whichshould have sufficient strength to ensure the frequent lifting andtransportation needs. Rust and paint inside and outside. The size of the wholeset is controlled at 7000×2200×2200 (mm) (300L diesel fuel tank)--increasingthe fuel tank to 600L and the size is controlled at 7500×2200×2200(mm) to meetthe road transport conditions of trucks. A check valve is installed at the end outletof the compressor gas, and the air supply valve port is a two-inch pipe thread.

Thewhole compressor has complete performance, reliable quality, easy operation andhigh work efficiency. It is suitable for field and harsh constructionenvironment (water, dustproof and shockproof). It is a mature styling productwith reliable control and easy maintenance.

Compressordesign and manufacturing refer to JB/T 10683-2006 "Medium and highpressure reciprocating piston air compressor"

Compressor Operation and MaintenanceManual

1.Before starting thecompressor

1.1Check whether the oil level of the compressor is within the range of the oilguage scale.

1.2.Check whether the screws of the compressor unit are loose.

1.3.Open all drain valves in the lower part of the instrument panel.

1.4.Open the total discharge valve.

1.5.Check whether the pressure gauge pointers at all levels return to “0†position.

1.6The lubricant temperature indicates whether the value is substantiallyconsistent with the local temperature.

2. Compressor Operation

2.1.After the compressor started, only the gas flow and mechanical rotation soundshould be heard. There should be no impact sound.

2.2.Close all drain valves one by one under the instrument panel.

2.3. Slowly rotate the total discharge valvehand-wheel clockwise, and observe the pressure gauge pointer slowly rising atthe same time. When the four stage pressure gauge pointer is stable at 20MPa,the first stage pressure gauge pointer should be between 0.25~ 0.29MPa, thesecond stage of the pressure gauge pointer should be between 1.27 ~1.59 MPa, the thirdstage of the pressure gauge pointershould be between 5.29~ 6.08 MPa, the fourthstage of the pressure gauge pointershould be within range 20Mpa.

2.4.The safety valves should be in the closed state during the compressor is normaloperating. If a certain safety valve is opened, the cause should be checkedimmediately, and the change of the corresponding pressure indication valueshould be observed. The opening of the safety valve is generally an abnormaloperation of the air valve.

2.5.Slowly rotate the drain valve under of the instrument panel every one hourduring normal operation of the compressor to exhaust the condensed water andtrace oil in the separator. At the same time, observe that the correspondingpressure gauge pointer should remain in the original position and it is noteasy to fall back.

2.6.During the normal operation of the compressor, the operator should continuallypatrol the inspection. To obsere the change of the indicator value, and theinstrument pointer allows for slight fluctuations.

3. Before stopping thecompressor

3.1.Open the total discharge valve and let the pressure gauge pointers at alllevels return to the “0†position.

3.2.Open all drain valves under the instrument panel.

3.3.Make the compressor to stop after running for 2~3 minutes under the unloadstate.

4. Replacement forLubricate oil

4.1.Normally for a new compressor need to replace new lubricate oil once its firsttime running for 50~100hours.( Special Note: as the compressor imported fromoverseas which may no lubricate oil, please kindly check clear if thereinjected enough lubricate oil. Kindly clear it completely,then after compressorrun 50-100hours to change the same brand lubricate oil)

4.2.Since first time replaced lubricate oil,then regularely replace the lubricateoil every 150hrs of operation.And the oil absorber must be cleaned.

4.3.When the operating ambient temperature is high or dusty, the oil replacementinterval should be shortened accordingly, and the oil filter should be replacedat the same time.

Inquiry to : keepwin@keepwin.com

Keepwin Technology HebeiCo.,Ltd

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email