- Home Page

- Company Profile

-

Our Products

- API 618 Reciprocating Compressor

- Diaphragm Compressor

- Integrated Compressor

- Scroll Compressors

- Screw Compressor

- Reciprocating Piston Compressor

- Reciprocating Compressor

- Natural Gas Compressor

- Hydrogen Gas Compressor

- Oxygen Gas Compressor

- CO2 & LPG Gas Compressor

- Fast Delivery Oxygen Booster Compressor (Piston)

- Membrane Nitrogen Booster Compressor

- Piston Compressor Air Valve Spare Part

- Water Chiller

- Medical Oxygen Gas Equipment Machine

- Compressor Equipment

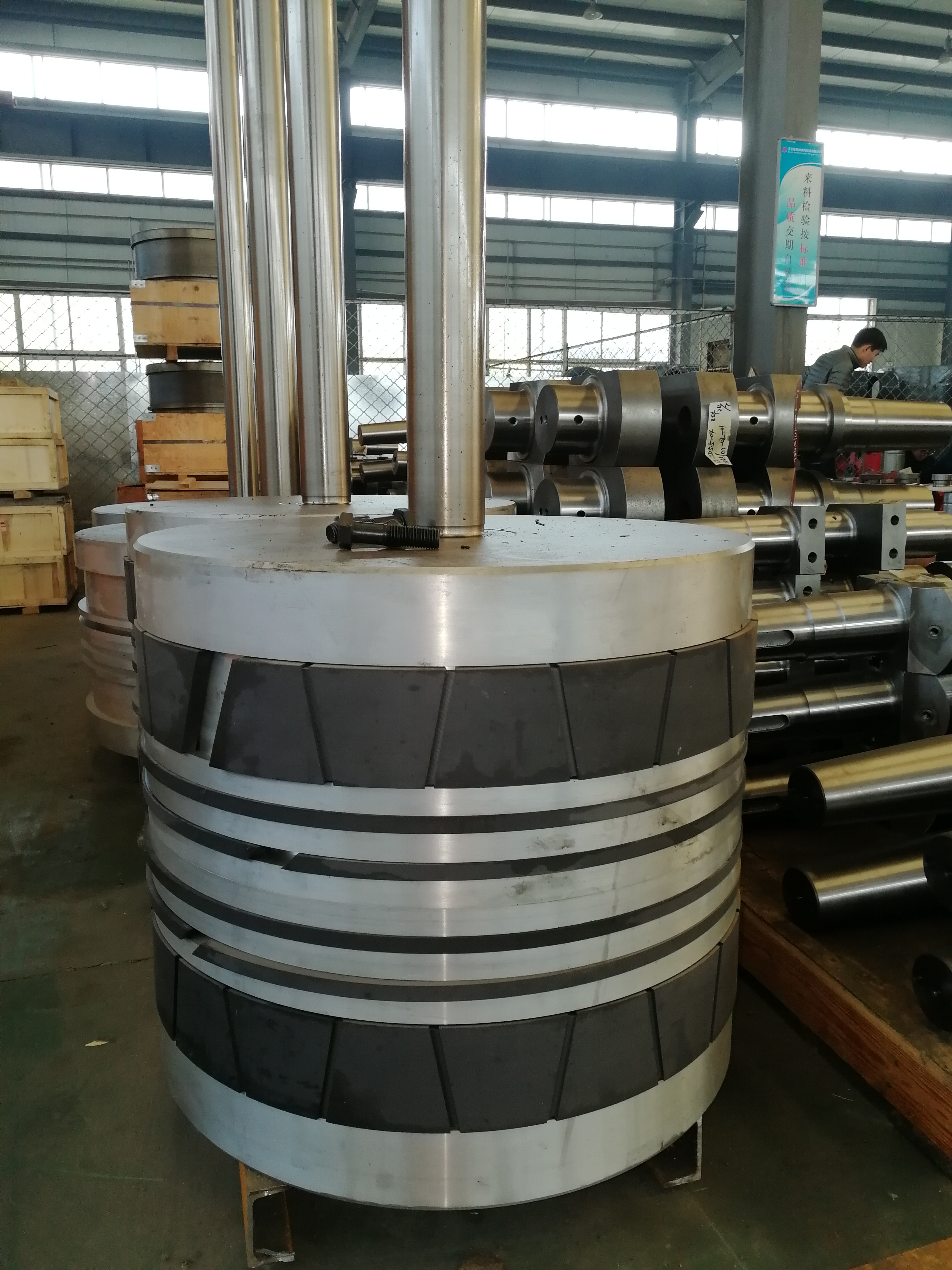

- Compressor Spare Part

- New Items

- Extra Link

- Contact Us

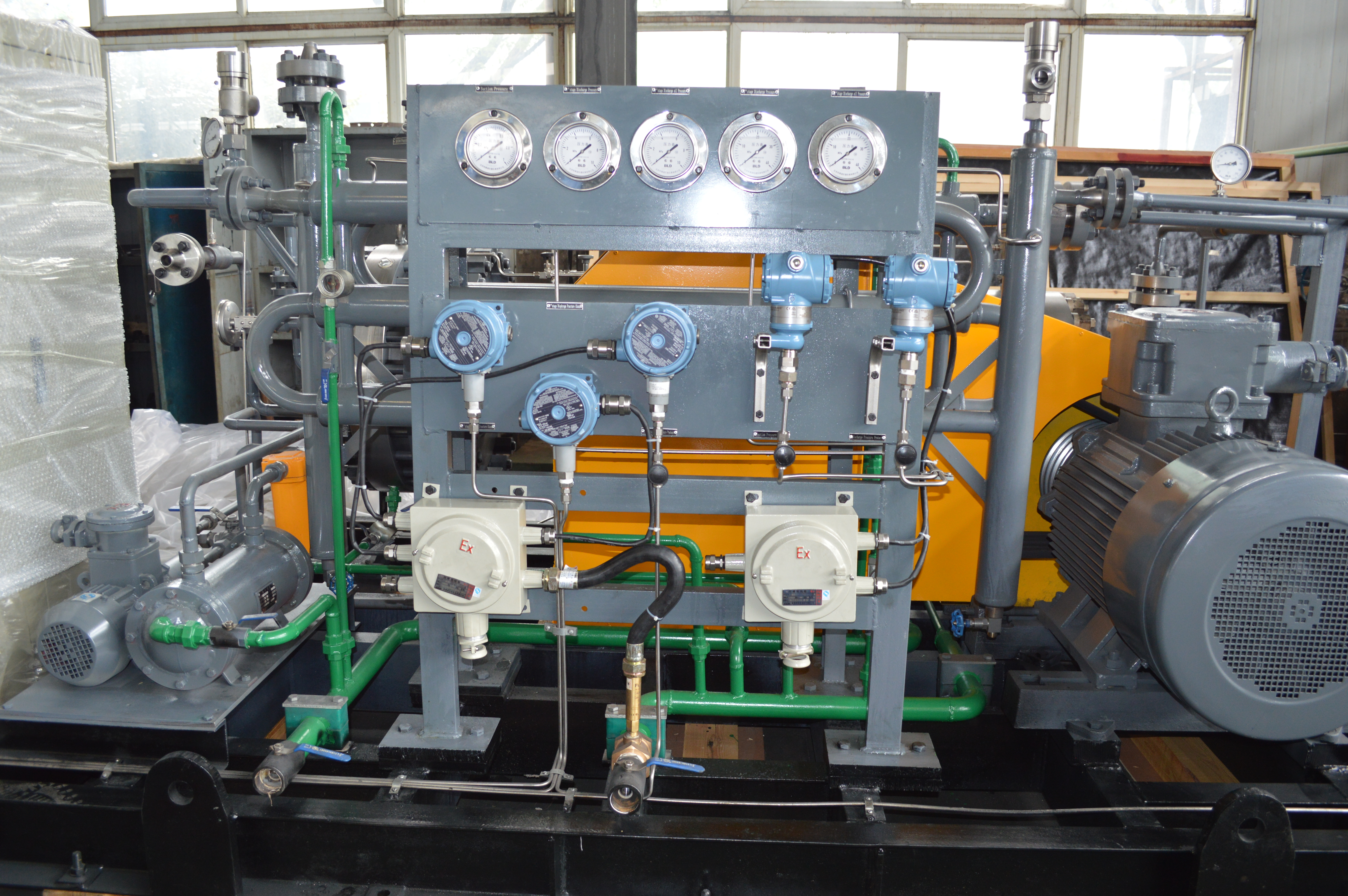

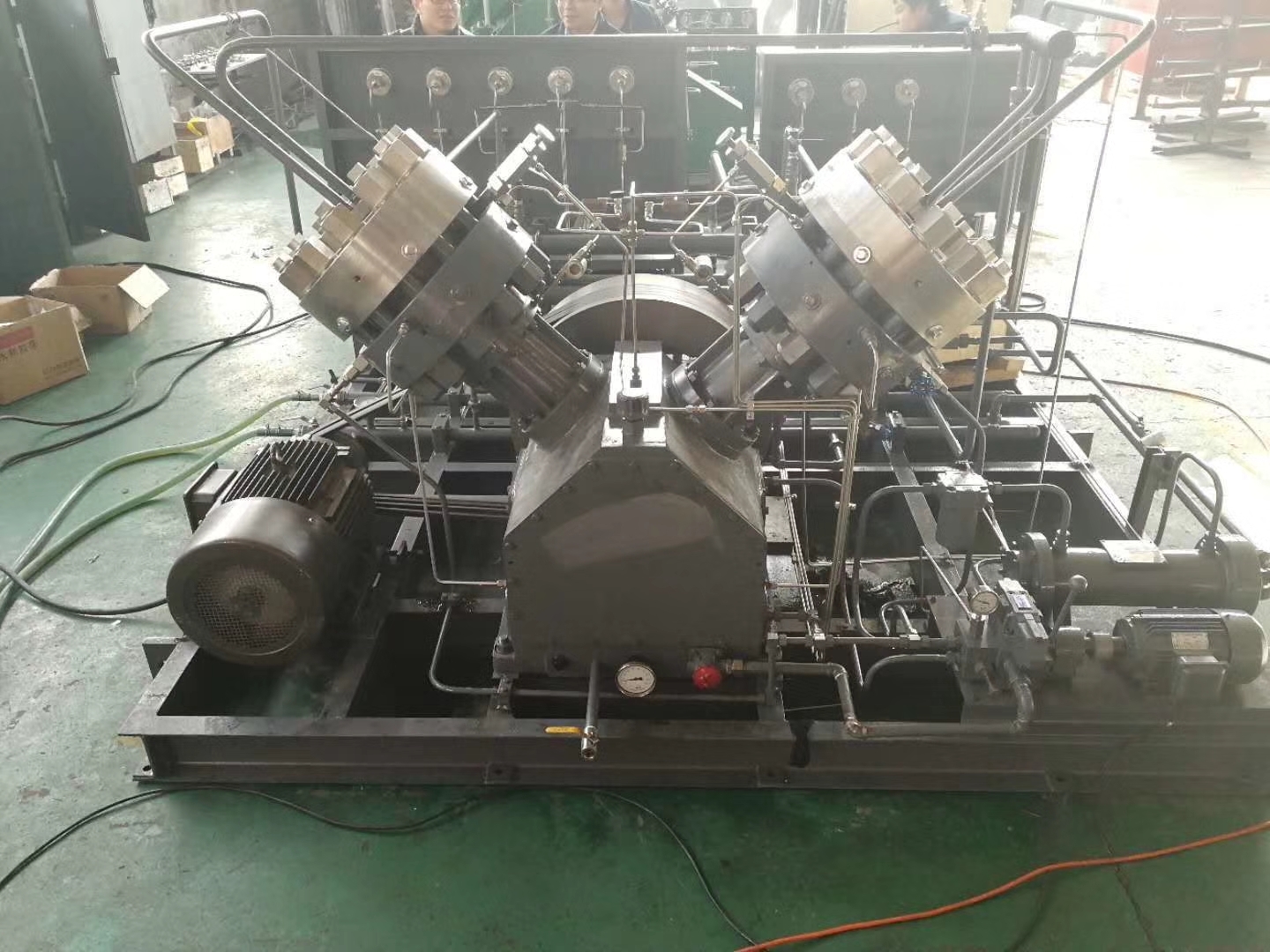

Industrial Reciprocating Gas Compressor

56980 USD ($)/Set

Product Details:

- Allied Equipment Cylinder

- Configuration Stationary

- Power Source Ac Power

- Silent No

- Lubrication Type Oil-Free

- Voltage any voltage can customize Watt (w)

- Driven Mode direct driven

- Click to View more

X

Industrial Reciprocating Gas Compressor Price And Quantity

- 1 Set

- 56980 USD ($)/Set

Industrial Reciprocating Gas Compressor Product Specifications

- 1year

- Ac Power

- direct driven

- Stationary

- Cylinder

- any voltage can customize Watt (w)

- No

- Oil-Free

Industrial Reciprocating Gas Compressor Trade Information

- Tianjin/Shanghai

- Paypal, Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Delivery Point (DP)

- 200 Set Per Month

- 90 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard export wooden case and waterproof bags or bubble film ,better protection for compressor machine.

- Australia, North America, Eastern Europe, Africa, Middle East, South America, Western Europe, Asia, Central America

- All India

- CE

Product Description

Capitalise on precision and power with our Industrial Reciprocating Gas Compressor, designed for crowning performance in demanding environments. As a proud exporter, distributor, manufacturer, and supplier in China, we bring you a splendid configuration-stationary, oil-free, with direct-driven technology. Procure your compressor in any voltage, tailored for your powering needs. Our valorous machine pairs perfectly with cylinder allied equipment and ensures reliable AC power operation. Pick yours today and experience reliability crowned with a 1-year warranty, setting new standards in industrial gas compression.

Versatile Application Method and Industrial Utility

The Industrial Reciprocating Gas Compressor is valorously engineered for seamless industrial application. Utilised across manufacturing plants, this stationary unit excels in supplying compressed gas for process operations, pneumatic tools, and cylinder filling. Its flexible AC power input and oil-free lubrication make it well-suited for plants demanding high levels of purity and operational reliability. This compressor is indispensable in sectors where uncompromised delivery and consistent performance are paramount.

Sample Availability, Secure Packaging, and Export Advantages

Discover our crowning value with sample availability to evaluate performance before procurement. Each compressor is packaged securely to prevent transit damage, ensuring pristine condition upon delivery. With our lowest price policy and transparent list price, we make sure your Purchase Order is as cost-effective as possible. Serving main export markets across the globe, our compressors are trusted by distributors, traders, and industrial leaders worldwide for reliability and long-term value.

Versatile Application Method and Industrial Utility

The Industrial Reciprocating Gas Compressor is valorously engineered for seamless industrial application. Utilised across manufacturing plants, this stationary unit excels in supplying compressed gas for process operations, pneumatic tools, and cylinder filling. Its flexible AC power input and oil-free lubrication make it well-suited for plants demanding high levels of purity and operational reliability. This compressor is indispensable in sectors where uncompromised delivery and consistent performance are paramount.

Sample Availability, Secure Packaging, and Export Advantages

Discover our crowning value with sample availability to evaluate performance before procurement. Each compressor is packaged securely to prevent transit damage, ensuring pristine condition upon delivery. With our lowest price policy and transparent list price, we make sure your Purchase Order is as cost-effective as possible. Serving main export markets across the globe, our compressors are trusted by distributors, traders, and industrial leaders worldwide for reliability and long-term value.

FAQ's of Industrial Reciprocating Gas Compressor:

Q: How does the Industrial Reciprocating Gas Compressor operate in plant environments?

A: The compressor operates as a stationary unit, driven directly by AC power and optimized for oil-free performance. It delivers consistent, high-quality compressed gas for various plant applications including pneumatic tool operation, process gas supply, and cylinder filling.Q: What are the main benefits of picking an oil-free reciprocating compressor?

A: Opting for an oil-free model eliminates the risk of oil contamination in the compressed gas, which is critical for industries requiring gas purity. This feature also reduces maintenance needs and supports cleaner, more sustainable plant operations.Q: When should I consider procuring a customized voltage configuration?

A: You should procure a customized voltage compressor when your facility operates on non-standard electrical supplies or requires integration with existing infrastructure, ensuring seamless compatibility and optimal performance.Q: Where can the compressor samples be obtained before placing a purchase order?

A: Samples can be requested directly from our distribution or export departments. This allows evaluation of performance and suitability before finalizing your purchase order at the lowest available price.Q: What is the process for placing an international purchase order?

A: To place an order internationally, contact our sales team with your requirements. After confirming the list price and specifications, issue a purchase order. We handle secure packaging and timely shipment to your designated export market.Q: What packaging details are provided for export shipments?

A: Each gas compressor is securely packed to international standards, ensuring it remains undamaged during transit. Detailed packaging information is supplied upon order confirmation, giving peace of mind to our export clients.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'New Items' category