- Home Page

- Company Profile

-

Our Products

- API 618 Reciprocating Compressor

- Diaphragm Compressor

- Integrated Compressor

- Scroll Compressors

- Screw Compressor

- Reciprocating Piston Compressor

- Reciprocating Compressor

- Natural Gas Compressor

- Hydrogen Gas Compressor

- Oxygen Gas Compressor

- CO2 & LPG Gas Compressor

- Fast Delivery Oxygen Booster Compressor (Piston)

- Membrane Nitrogen Booster Compressor

- Piston Compressor Air Valve Spare Part

- Water Chiller

- Medical Oxygen Gas Equipment Machine

- Compressor Equipment

- Compressor Spare Part

- New Items

- Extra Link

- Contact Us

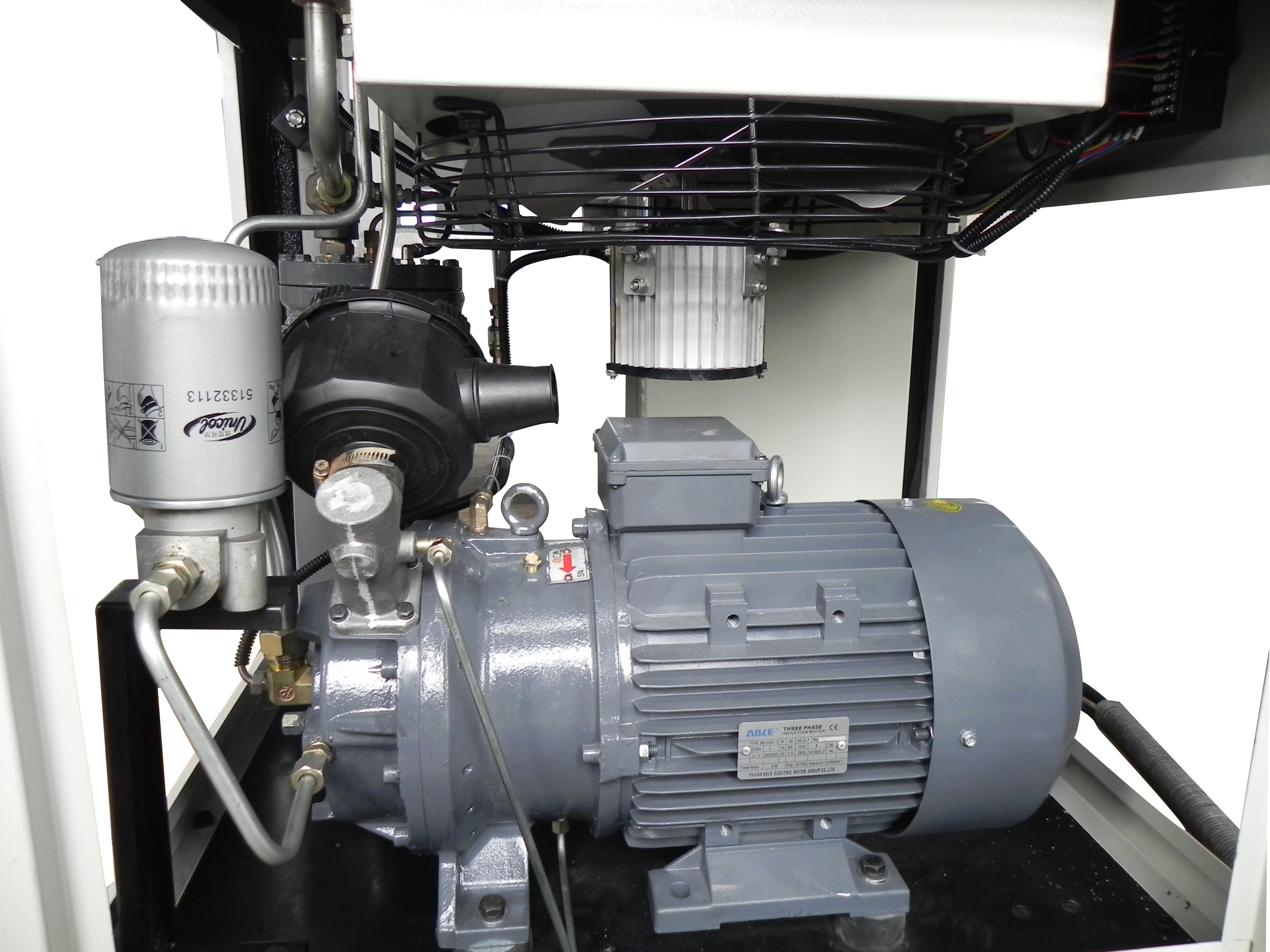

Mounted Oil Inject Compressor

2000 USD ($)

Product Details:

- Type Of Compressor Other

- Allied Equipment Air Tank

- Configuration Stationary

- Power Source Ac Power

- Silent Yes

- Lubrication Type Lubricated

- Voltage 380 Watt (w)

- Click to View more

X

Mounted Oil Inject Compressor Price And Quantity

- 2000 USD ($)

- 1000.00 - 90000.00 USD ($)

- 1 Set

Mounted Oil Inject Compressor Product Specifications

- 380 Watt (w)

- Ac Power

- Lubricated

- Air Tank

- Other

- Stationary

- 1year

- Yes

- direct drive

Mounted Oil Inject Compressor Trade Information

- tianjin/Shanghai

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cash in Advance (CID), Cash Advance (CA)

- 2000 Set Per Month

- 90 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard export wooden case and waterproof bags or bubble film ,better protection for air compressor.

- Australia, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia, North America

- All India

- CE ISO

Product Description

Standard Medical hostiptal use Mounted Oil Inject Scroll Compressor

1. More than 50% power saving than piston machine

2. Bearing life is more than 20000H (service life 5-10 years)

3. Suitable for medium pressure machine 1.6Mpa application

4. High concentricity, low noise and compact structure;

5. The number of parts is reduced and the cost is greatly reduced.

Depending on clients requirements, we are involved in manufacturing, supplying and exporting a wide range of Mounted Oil Inject Compressor with different pressure ranges. It is designed by using high grade components and modern techniques under the stern guidance of our experts. The material used for manufacturing this compressor is procured from the reliable vendors of the market. Apart from this, we provide this Mounted Oil Inject Compressor to our valued clients at budget friendly prices.

World Top Quality

Factory direct sell price for Air Compressor

Energy saving, High efficiency

Low noise, Lower maintenance cost

KP-WX series Oil Free Scroll Air Compressor

More lower noise and Convenience

According customers' require to customize

More less parts and wearing parts, high quality air supply, excellent durability than screw type compressor.

Simple operation, beautiful appearance and energy saving design

Static and dynamic disk without contact, No wearing parts, save maintenance cost,

1 class energy saving, continuous and stable exhaust, high volume efficiency;

World Top Quality

Factory direct sell price for Air Compressor

Energy saving, High efficiency

Low noise, Lower maintenance cost

KP-WX series Oil Free Scroll Air Compressor

More lower noise and Convenience

According customers' require to customize

More less parts and wearing parts, high quality air supply, excellent durability than screw type compressor.

Simple operation, beautiful appearance and energy saving design

Static and dynamic disk without contact, No wearing parts, save maintenance cost,

1 class energy saving, continuous and stable exhaust, high volume efficiency;

World Top Quality

Factory direct sell price for Air Compressor

Energy saving, High efficiency

Low noise, Lower maintenance cost

KP-WX series Oil Free Scroll Air Compressor

More lower noise and Convenience

According customers' require to customize

More less parts and wearing parts, high quality air supply, excellent durability than screw type compressor.

Simple operation, beautiful appearance and energy saving design

Static and dynamic disk without contact, No wearing parts, save maintenance cost,

1 class energy saving, continuous and stable exhaust, high volume efficiency;

| Compressor Model | KP-WX-30 | KP-WX-60 | KP-WX-120 | KP-WX-180 | KP-WX-240 | KP-WX-300 |

| Nominal Pressure bar g | 7.5 | 7.5 | 7.5 | 7.5 | 7 | 7 |

| Drive motor Kw | 4 | 5.5 | 11 | 16.5 | 22 | 27.5 |

| FAD m3/min | 1.2 | 0.6 | 1.2 | 1.8 | 2.4 | 3 |

| Noise lever ,1m dB(A) | 62 | 65 | 65 | 67 | 67 | 68 |

| Weight kg | 150 | 170 | 440 | 630 | 820 | 1000 |

| Discharge air temperature | 50 | |||||

| Driving mode | Belt Drive | |||||

| Matching motor type | Three phase asynchronous motor | |||||

| Motor Current A | 8.4 | 11.4 | 22.8 | 34.2 | 45.6 | 57.8 |

| Relay Current A | 12.8 | 17.6 | 35.2 | 52.8 | 70.4 | 88 |

| Exhaust outlet pipe diameter | 3/4 Globe valve | 3/4 Globe valve | 3/4 Globe valve | 3/4 Globe valve | 1 Globe valve | 11/2 Globe valve |

| Dimension (LWH) mm | 800695830 | 800695830 | 11007001300 | 145011001300 | 155012501350 | 165013501550 |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'New Items' category